The COANDA effect : What is it and what is it used for?

Date

The Coanda effect is named after the Romanian engineer Henry Coanda, born in 1886. It is a physical phenomenon described as the attraction of a jet of fluid (liquid or gas) to a convex surface over which it flows. In this way, the fluid follows the surface and undergoes a deviation before detaching from it with a different trajectory to the one it had upstream.

This phenomenon can be described as a “stationary bifurcation in a fluid flow”.

On the other hand, a solid approaching a convex object would have a trajectory related to a ricochet, as in the examples below.

WHAT CAN THE COANDA EFFECT BE USED FOR?

- In aeronautics: The Coanda effect is partly responsible for the way an aircraft wing works. The phenomenon of lift is made possible by the air passing under the wing of the aircraft; the air exerts a thrust on the wings of the aircraft and prevents it from falling by gravity, keeping it aloft; when the aircraft decelerates, there is less air flow and the aircraft gradually loses altitude.

- In automotive engineering, another example can be seen: the air following the upper aerodynamic curve of a car’s bodywork and spoiler presses the car against the ground thanks to the induced suction effect under the vehicle to improve its grip on the road.

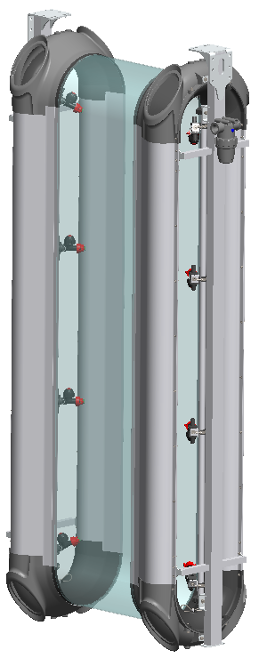

- En viticulture : Chez Bliss-Ecospray, nous avons breveté un usage différent de l’effet Coanda. Il s’agit d’améliorer le traitement des vignes avec une gestion aéraulique des sprays de pulvérisation. Ainsi, l’effet Coanda s’applique à deux reprises sur l’écoulement de l’air, en bleu et en rouge sur la figure 5 ci-dessous.

When the air follows the inside walls of our rings between the front and rear blades, there is an induction phenomenon and the Coanda effect accentuates and directs the flows to confine the spraying and improve the quality of application of the products on the vines.

A Coanda effect also occurs when the airflow exits the lip of the downpipe. The outer lip of the downspout is shorter than the inner lip, creating an additional induction effect that causes the air to flow at a slight angle towards the inside of the ring. The design of Bliss Ecospray therefore creates a high-performance laminar blade of air, regular and controlled in its trajectory for optimum spraying and safe treatment of vineyards, with greater economy, ecology and performance in terms of managing sanitary pressure.

This air gap is present all around the ring, so spraying takes place inside the air shield, which is the source of improvements and innovation.

Figure 6 : Turbulence in the heart of the vegetation = better coverage